Designscape's factory boasts of a sprawling production area spanning over 90,000 sq. ft., where a combination of state-of-the-art automated machinery and hand tools produces modern furniture with a world-class finish.

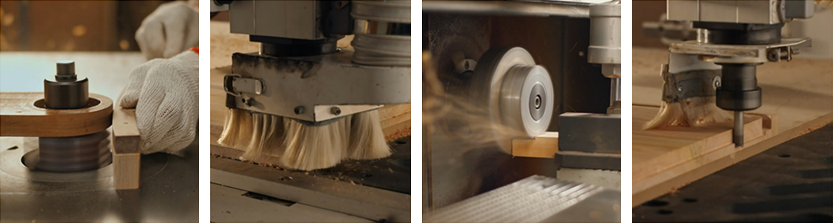

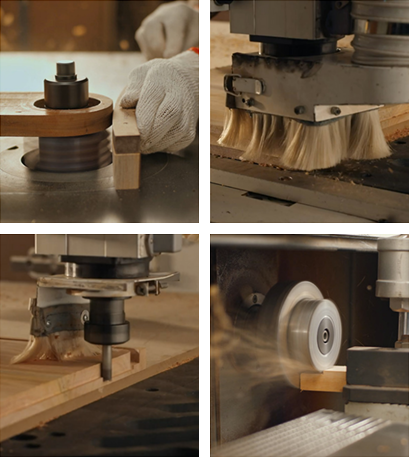

Our manufacturing unit is fully-equipped with the latest technology and advanced machinery, including forklifts, screw air compressors, spindle shapers, wide belt sanders, sanding machines, pneumatic cut-off saws, wood copy lathes, CNC tenoners, radial arm saws, dovetail joints, hydraulic press, double-end tenoners, amongst others. The high-tech machines are fully capable of producing furniture and products with sleek curvatures and a unique finish along with customizing designs as per the client's requirement.We work with premium-quality hardwood, metal, glass, fabric and rexine and our dedicated units seamlessly perform various functions such as cutting, contouring, sanding, lacquering, upholstering, etc.

Area

90,000 Square

Feet

Capacity

3600+ Sets Per

Month

Machine

Highest-grade Wood and

Metal Processing Machines

Employees

200+ Employees

Location

Mawna Uttarpara,

Sreepur, Gazipur

With fully-mechanized, end-to-end processes that begin from locally sourcing fully-aged hardwood, to crafting every component, to producing ready-to-use products that are delivered within just 14 days, Designscape has revolutionized the industry with its design philosophy and brought a shift in the way people buy furniture.

Sonargaon Series for ISHO

Ikat Series for ISHO

Ratargul Series for ISHO

These videos succinctly display the origin of the designs and how the ideas are brought to life at the Designscape factory to form sleek, modern and ready-made furniture, while also showcasing the design process that pays a tribute to the country's treasured heritage and materials. The video also highlights the various different stages of production at the Designscape factory starting from design till finishing.